Finishing

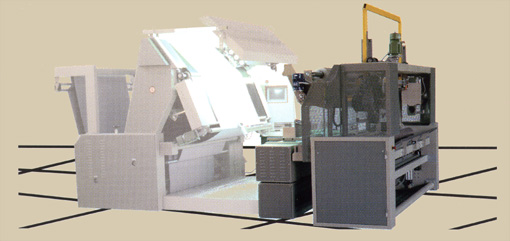

MP 2000 - AUTOMATIC PACKING

MACHINES FOR ROLLS

This compact model is normally

installed in line with fabric inspection tables

for wrapping finished rolls.

If fed with suitable material,

it is also capable of wrapping rolls of fabric

from several machines.

The MP 2000 is designed to

insert the leading edge of the heat-shrink polyethylene

sheet (thickness 50-80 microns) into the roll,

giving excellent adhesion of the plastic to

the roll itself.

Absolute protection of the

finished roll of fabric is guaranteed by hot

air systems which seal the ends of the roll.

The machine consist of:

- automatic pincers for inserting the leading

edge of the polyethylene sheet fed from

a roll situated in the upper part.

- sheet winding station with thermobonding

by pulse operated resistors; automatic adjustment

to roll circumference. On completion of

the wrapping operation, the station off-loads

the roll into a specifically designed container.

- electric polyethylene sheet cutter.

- side seal with two hot air heater groups

mounted on independent vertical and horizontal

runners, with automatic roll diameter and

width search;

- energy saving air heaters which operate

only during bonding operation.

Accessories

- load cell operated roll weighing module

(on entry), with weight display and serial

connection to PC.

Production Capacity

- 100 to 120 packed rolls per hour

TECHNICAL

SPECIFICATIONS |

| Max.

roll length |

2100

mm. |

| Max.

diameter |

650 mm. |

| Power

supply |

220V/380V

x3phase + T neutral 50 Hz |

| Absorption |

5 Kw/h |

| Air consumption

(per cycle) |

120 NL |

| Total

machine weight |

1800

Kg. |

DIMENSIONS |

| Length |

3500

mm. |

| Width |

1155

mm. |

| Height |

1970

mm. |

Back

|